2.6. The Principle of Prestressing

2.6.1. Summary

By analogy of principle with the prestressing used in the reinforced concrete buildings, the Prestressing of the assembly bone-prosthesis consists in putting in tension the bone so that there remains always compressed in direction of the implant.

The goal is to prevent that the implant does not leave the contact with the bone at the time of loadings whose orientation is unfavorable.

2.6.2. The example of prestress in architecture.

So that a massive material, subjected to forces tending to fissure it, does not fissure or that two elements of a discontinuous assembly always remain in contact even if they are subjected to forces tending to separate them, one must apply by advance, the permanent forces being opposed to cracking or separation, forces which must be higher than those which tend to separate them.

The principle of prestress in the building is to compress in advance and elastically the areas of the concrete which will be, after be put in service, subjected to tractive efforts. This result is obtained by insertion, in the mass of the concrete, of powerful sufficiently tended steel wire ropes so that they continue to tighten the concrete even at the time of extreme loads.

The concept of prestressing, applied mainly in the construction of f reinforced concrete structures, can be extended to other fields.

2.6.3. The problem to be solved: prostheses only “wedged”

At the time of the installation by impaction of a stem of prosthesis in the shape of wedge, whose sides decrease obviously towards the point, but without controlled geometrical relation, the implanted stem is immobilized when the operator considers resistance to the penetration sufficient. The osseous bed is subjected to pressures which are in nondefinite zones of the osseous bed and whose intensity is unknown, but excessive. At the intense contact points, these pressures exceed what the bone can support. In these places, the bone resorbs, the micromovements occur, the osseous bed widens locally and the stem is sinking.

This sinking continues until the entire surface of the carrying contact between the bone and the implant is sufficiently extended and which the bone is again subjected to constraints included in the Field of Bone Vitality.

Penetrations of more than 1 cm were frequent with the Zweymüller stems of first generation. Obviously, the situation could not be stabilized because the osteointegration could not take place. During a few years, this process was regarded as normal and as a fate inherent in the stems without cement.

2.6.4. The constraints are not prestress

I want to remind that the stems of Zweymüller of first generation (1979-1985) satisfied neither the conditions of the Pyramidal Base Form nor those of the Conical Junction in the bone.

The fact that these stems have a rectangular section and 4 longitudinal edges by no means guaranteed a conical junction with the bone because the position of these 4 edges was too far away from the pyramidal form.

The final impaction of course provided tension on the bone but only in the frontal plane, that is to say in the direction of the width of the stems. In the anteroposterior direction, the behavior remained close to the “wedging” that I mentioned previously. Antero-posterior micromovements often occurred and, with my hands, I observed amplitudes of one millimeter after impaction.

Thanks to previous observations, I understood in 1984 that if I adopted a pyramidal shape for the anchorage zone, because a pyramid belongs to the mathematical family of cones, the junction of a conical nature with the bone bed would be achieved.

2.6.5. Prestressing extended to prostheses.

I therefore introduced into my method of calculating the corresponding stems and rasps, formulations which guarantee the obtaining of a controlled Prestress.

In my opinion, the bone must never undergo extreme stresses exceeding the threshold of resorption by excess of stress and simultaneously the bone must not be totally unloaded either. The momentary total discharge occurs in particular if, during the walking cycle, the surface of the implant has the possibility of moving away from the surface of the bone at the point in question.

To satisfy this condition, Primary Stability must be achieved and the bone must remain in the Bone Vitality Range. I looked for a solution so that the prosthetic rod was no longer, as before, "stuck", that is to say suspended in a few contact zones of small surface, but put in pre-stress, over a large surface, at the time of impaction.

2.6.6. The process of establishing prestress.

With a stem whose edges constitute a shape sufficiently close to the pyramid, and a preparation of the bone bed, with Impaction Reserve, by the corresponding calculated rasp, the assembly immediately presents a large contact surface , but it is obvious that contact cannot take place everywhere. All the constraints are distributed over this large surface.

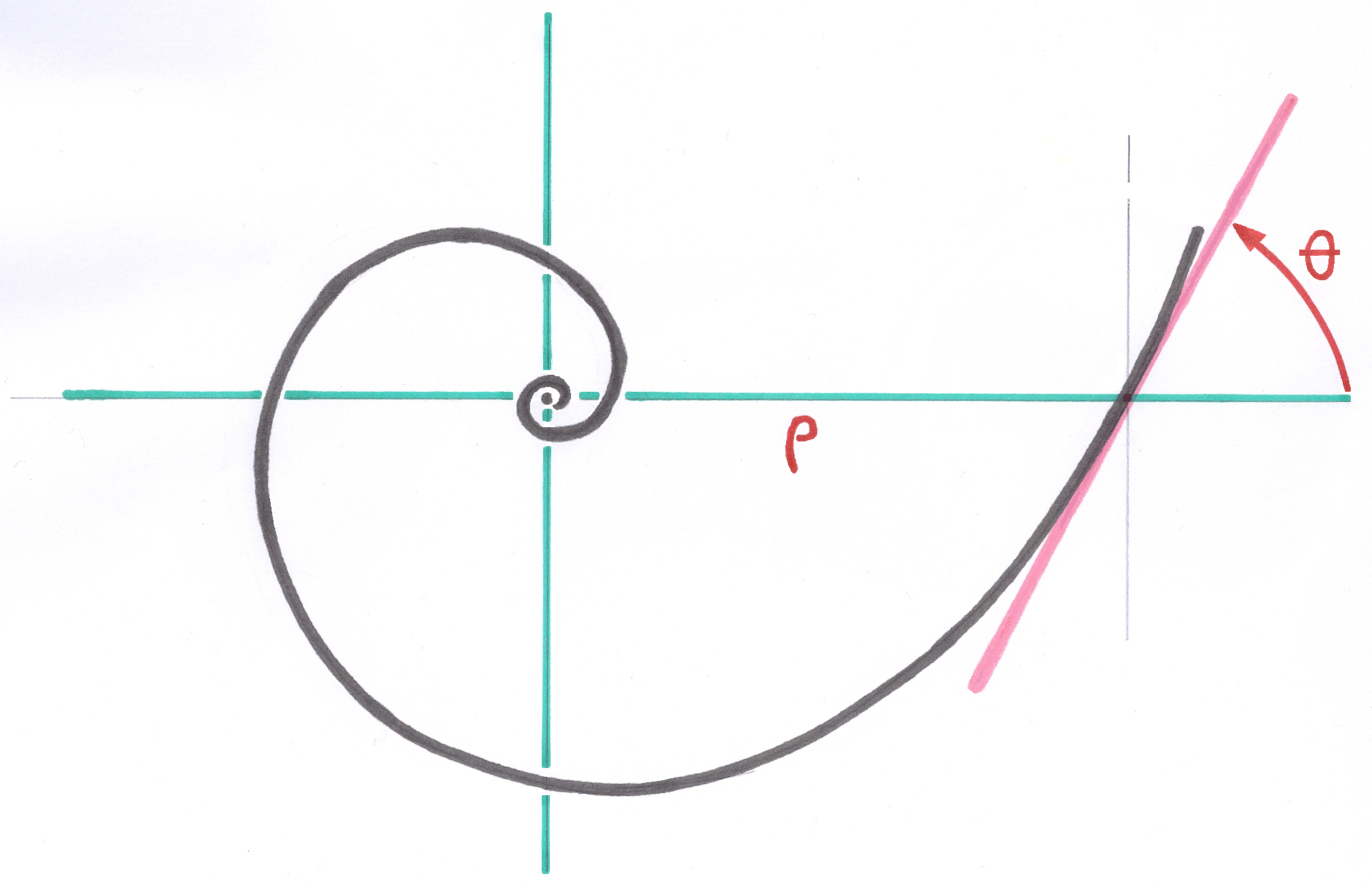

The impaction at the end of implantation places the bone in tension simultaneously, all along the stem, medial-lateral and antero-posterior. Ideally, the tensions are oriented in radial directions, i.e. all seeming to come perpendicular to the longitudinal axis of the pyramidal stem. The Principle of Distributed Constraints is respected.

Over a maximum surface area, the bone is pressed against the metal rod with forces greater than those which would tend to move the rod away from the bone during peak loads.

The Prestress is established.

----