5.3.4. Inlays Bicon Metal-Metal

5.3.4.1. Metal-to-metal sliding with “sandwich” technology

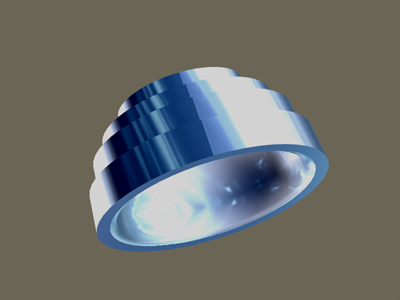

To be able to retain a significant part of the flexibility of the Bicon cup system, designed with a flexible metal shell and a Polyethylene insert fixed by Multicone Junction, the metal insert did not have to be massive. The important benefits of accelerated osseointegration and elimination of all migration would have been lost.

I preferred to keep the best possible thickness of Polyethylene so that the small dynamic deformations of the pelvic bone, transmitted to the Titanium shell via the fins, are cushioned by the flexibility of the Polyethylene.

5.3.4.2. Thickness of the metal part

I wanted the thickness of the metal of the seat to be moderate to allow minimal residual elasticity. For this purpose, I have planned for the sliding seats with a nominal diameter of 28, a thickness for sizes 1 to 3, and a slightly greater thickness for sizes 4 to 9.

5.3.4.3. Clearance between sliding surfaces

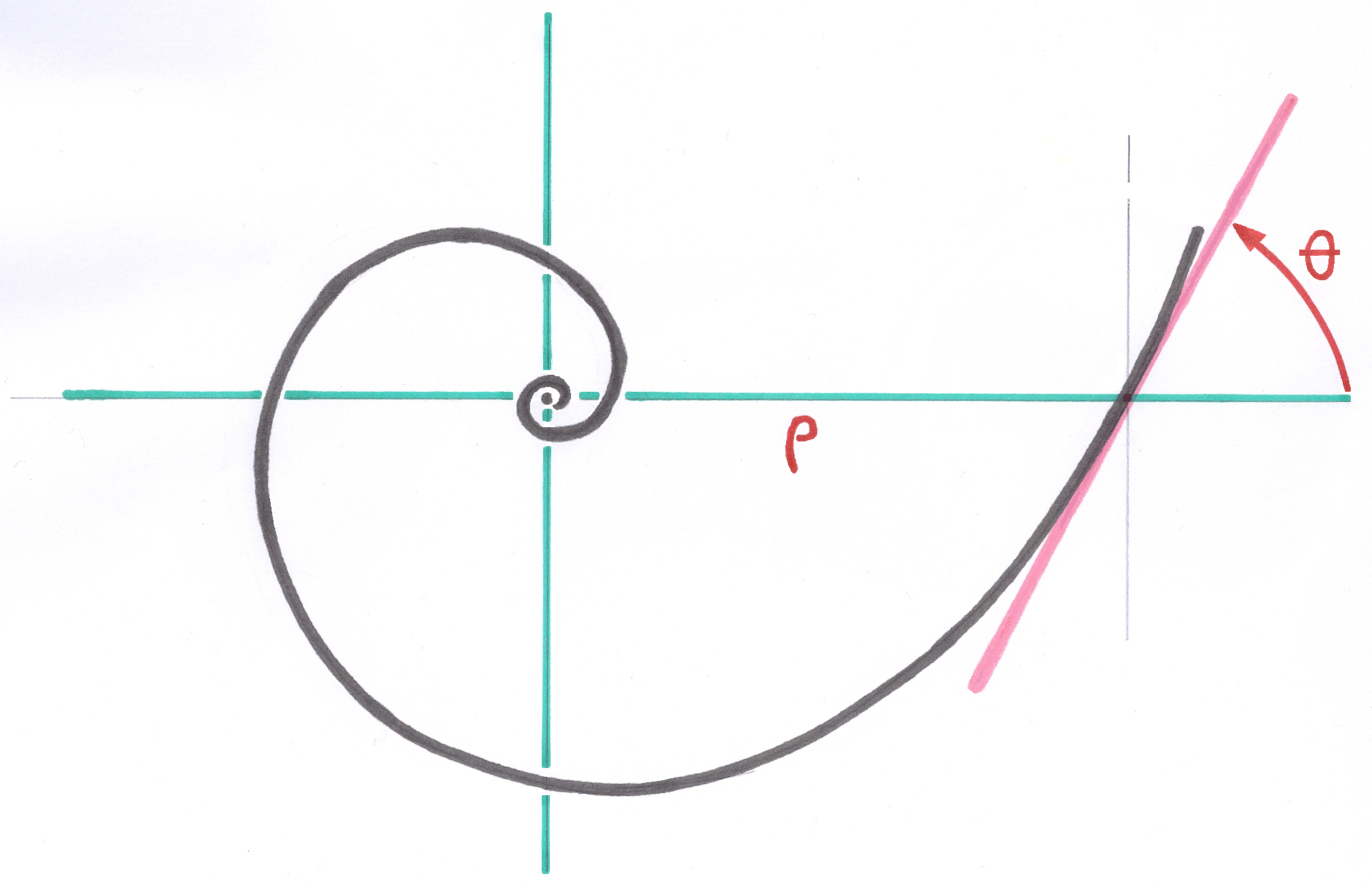

As with all spherical sliding surfaces, clearance must be reserved between the head and the hollow sphere of the insert. This clearance must be much lower than that of the Metal-Polyethylene couple but slightly higher than the clearance of the totally rigid Ceramic-Ceramic couple at the considered scale . If the clearance of the Metal-Metal torque is insufficient, a seizing or "disc brake" effect may occur during peak loading of the prosthesis with a risk of abnormal wear of the metal surfaces.

5.3.4.4. Choice of metal material

The Manufacturer of the sliding seat and associated heads has itself defined its requirements with regard to metal alloys, their treatment and their surface finish. My role was limited to the specific definition of the multicone junction and the external dimensions of the metal part.

5.3.4.5. Multicone junction

This metal seat was fixed in the insert by a suitable Multicone Junction. Unlike other applications that I have made, this Multicone Junction takes place between an incompressible metal part and a much more deformable material, Polyethylene.

The use, on either side of the Polyethylene part, of the Multicone Junction which is constituted by frustoconical steps adapting in successive steps to the general biconical shape of the outer Titanium shell and to the general spherical shape of the metal sliding seat, allows you to obtain the best thickness of Polyethylene.

Monoconical junctions would not have made it possible to maintain in all areas this thickness of the Polyethylene essential for its shock-absorbing function.

The Polyethylene block, when inserting the seat, due to the impaction of the conical junction had to slightly increase in diameter including the external diameter.

Knowing the Impact Reserve, the expansion at the junction with the seat was calculable. I evaluated the increase in the external dimensions of the insert and reduced accordingly, for manufacturing, the radial dimensions of the Polyethylene part.

At the beginning, for a few series produced, this reduction, planned to compensate for the expansion due to the installation of the metal seat, was not taken into account by the Producer. The radial dimensions of the solid polyethylene insert have been reported identically. In some cases, this led to difficulty installing the Polyethylene-Metal insert, which was larger after assembly than I had wanted.

5.3.4.6. Polyethylene Thickness

Using the Multicone Joint, like a sandwich, on both sides of the polyethylene, on the shell and seat sides, allowed us to maintain a sufficient polyethylene thickness, in my opinion.

For small shell sizes and 28mm heads, significant polyethylene thicknesses were not feasible.

During the European Standards meetings, I had to explain that Polyethylene used in a "sandwich" and prestressed by the two multicone junctions between two metal parts, presents absolutely no risk of creep.

The supporters of "large" thicknesses of Polyethylene (6mm), influenced by the defenders of 22mm heads, thinking only of the possible creep of Polyethylene, were difficult to convince.

----

Corresponding Patent: Patent Kupplung Multicon

Next implant: