5.1.1. Stems AlloClassic

5.1.1.1. The imperfections had to be corrected

As evoked in Introduction 1. , the development of the series of AlloClassic stems was started by all the personal observations during my participations in the implantations of the Zweymüller stems of first generation, also by criticisms of the users bringing back the complaints of their patients to me.

Certain users, including personal friends of several years, expressed me the regret to have to leave this technique which they found indefensible with respect to their patients.

To solve the majority of the difficulties encountered by the Operators and to satisfy the patients, I proposed a complete recasting of the system of prostheses of Zweymüller knowing that I could apply to it my studies of acquired mathematics and data processing a few years before to the Faculty of Science of Paris.

5.1.1.2. The first mathematically designed hip prosthesis

I could be able to establish, without external participation, new theories and to conceive of A to Z implants defined by calculation of which I could transmit to manufacture, coordinates, dimensions and of the final results which would not require any additional development. I could access, to perform these calculations, the supercomputers of the time, Control Dated 6600, then CRAY-One of a great Research organization.

My method did not have anything common with a.CAD, computer-aided design based on the drawing.

My computing system making it possible to start again a complete calculation as long as I was not entirely satisfied with the results, it was possible to calculate a good number of series of experimental stems, without needing technical designs or material prototypes to reach the final version.

It is the 37th version and recalculation of all the coordinates which was used to construct the AlloClassic prototypes.

This version, unchanged for 40 years, is used to produce all the AlloClassic stems.

In a few weeks, the prototypes of all the sizes and corresponding rasps were carried out. December 18th, 1984, in the Laboratory of Anatomy of a large Hospital in Vienna, we carried out a long meeting of experimental implantations on tens of femurs to objectively compare the Zweymüller stems of first generation and the prototypes of the new AlloClassic stems and their qualities of implantation and filling of the diaphysis.

After preparation and implantation, the femoral diaphyses implanted with stems of first generation and AlloClassic prototypes, were sawn in half lengthwise and I photographed all the samples. The observation of the differences and the results immediately astonished Professor Zweymüller. This version was adopted and I continued the development of the details to make it producible in series.

This series, in fact, has been mass produced and marketed two years later, in 1986.

5.1.1.3. The interlude of the so-called “Hochgezogen” stem

For reasons unknown to me, the Sulzer company preferred to develop a very slightly modified version of the first generation stems. The difference consisted of removing the 4 oblique cylindrical grooves close to the edges of the anchoring zone then drawing vertical lines to extend the central thickening of the anchoring zone up to the cutting plane of the neck. This version was publicly called "Hochgezogen" (extended upward).

5.1.1.4. The problem of laser marking

I had before pointed out with the production the risk that marking with the laser practiced into full on a very thinned zone, located under the collar, could weaken the mechanical resistance of the stems "hochgezogen".

My study in 1969, in the departement of Ophthalmology of the Hospital of the armies e Val-de-Grace, on the effects of the first medical laser on the Retina, had shown unexpected effects.

The Stereo Retinograph Zeiss showed that if the laser beam were focused in front of the Retina, because of a too strong convergence, tiny balls of boiling or even of explosion at the place of strongest concentration of the laser beam had appeared in the vitreous body.

It has been necessary to wait nearly two years and that this technological problem appears on the stems “Hochgezogen” so that my project of second AlloClassic generation is started again in urgency, after a crisis meeting of all the executives of the AlloPro company.

In the titanium of the stems, this phenomenon was predictable with marking lasers, which are much more powerful than ophthalmological lasers. The laser beam focused below the surface of the metal melted the metal along the marking, causing the titanium alloy to recrystallize as an amorphous metal, destroying its fundamental properties as a wrought metal.

But how beautiful the shiny marking was!

This marking, bilateral, was unfortunately located in the thinnest place, which was subject to antero-posterior constraints on the neck. Several dozen stems broke exactly along the marking. This is what motivated the rapid withdrawal of this prosthesis from the market.

It is thus only end of 1986 which my project of AlloClassic stems was produced in great series by SULZER. To date, no fracture of stem was brought to my attention. Thereafter, during my fifteen years of permanent participation in the Committees of standardization, I always supported the laser positioning of markings on zones not undergoing constraints.

5.1.1.5. The Geometric Anchoring of AlloClassic

The AlloClassic stem calculated in 1984 did not profit yet from all the advantages brought by the developments which I added to Geometrical Anchoring thereafter.

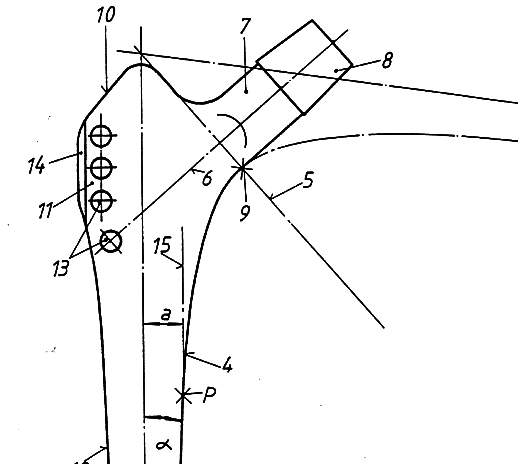

It already satisfied, without compromise, the principles of Conical Junction in Bone (2.3.), Primary Stability (2.2.), the Field of Osseous Vitality (2.4.), the Distributed Constraints (2.5.), Prestressing (2.6.) and the Principle of Extractibility (2.8.).

The Optimized Sizes (32.) of the AlloClassic series were calculated by the method of the Growing Factors (3.1.), its anchoring zone was built as the Pyramidal Base Form (4.2.). The series of stems was calculated with the method of the Thickness Corrections (4.8.)and satisfied the Principle of Ascending Interlocking (4.7.).

All the longitudinal edges of all the sizes of the AlloClassic series are provided with the same constant round-off of approximately 1mm, not yet formulated but definite during the production.

The heavy method of the Calcar Polynom, and the processes of Separation Function, of Impaction Reserve and the calculated chamfers were developed later and benefited the stem SL Plus.

5.1.1.6. The hyperbole of the calcar curve

One of the interesting characteristics of this AlloClassic stem is the mathematical curve which I used for the transition between the anchoring zone and the neck, to replace the usual arcs of circle.

The anchoring zone is connected to the base of the cylindrical rectilinear collar by an arc of hyperbole, whose regular variation is the excellent first modeling of the medial interior form of the proximal femur. (Patent 9.8.1. )

The low number of conflicts with the calcar is one of the explanations of the good adaptation of this stem to the great variability of the forms of the proximal zones of the femurs.

Thanks to these properties, the AlloClassic stems, unchanged for 39 years, have been currently distributed by the group ZIMMER, satisfy always more than two hundred Operators. Publicity 2003:

Sources de cette publicité:

http://www.zimmer.com/web/enUS/pdf/Alloclassic_Hip_System_Brochure_1001-25-011_11_03.pdf

----

Patent concerned: [AlloClassic Stem Patent] (/de/dokumente/patente/patent_schaft_alloclassic.html)

Next Stem: Stems Sl-Plus