5.2.2. Stems Dustmann CS Plus

5.2.2.1. A cemented stem derived from Geometric Anchoring

Although definitive fixation in the bone does not occur through large-surface contact of the stem with the bone wall, the maximum properties of Geometric Anchoring have been applied to this cemented stem.

The sizes are a series of Optimized Sizes calculated using the Growth Factor method. All sizes follow the principle of Ascending Interlocking, and moving from one stem size to the next results in a rise in the head, thus increasing the total bone length by a predictable amount.

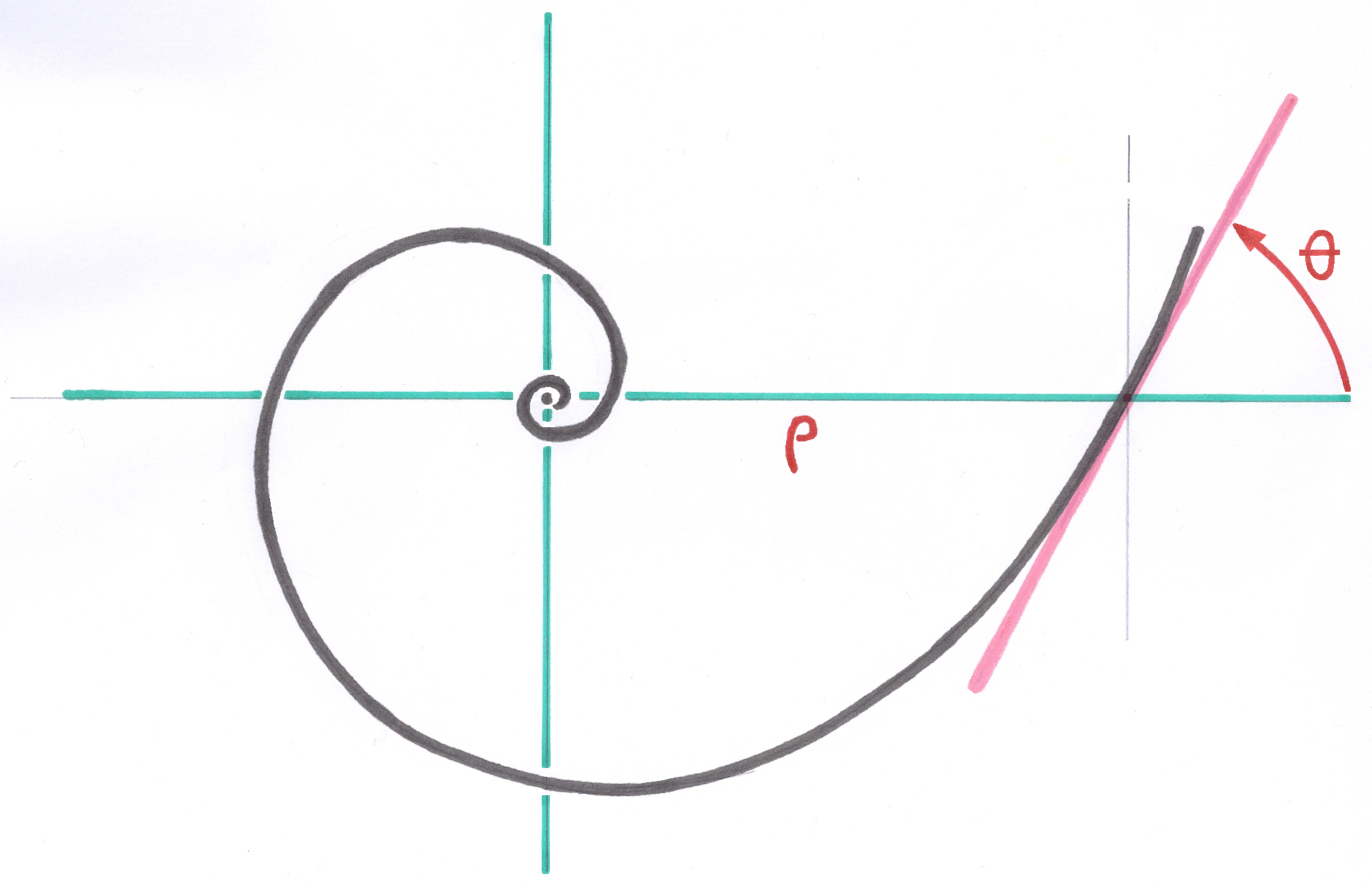

The Growth Center is located at the intersection of the anchor zone axis and the neck axis. From this point, stems elongate regularly with a specific Growth Factor, and necks elongate with a different Factor.

The stem width varies by a factor to accommodate the wide variety of medullary canals. The stem thickness varies regularly from the tip to the proximal region and from one size to the next. These stems have a relatively simple exterior structure.

5.2.2.2. Good adaptation to cementing

The discreet collar of these stems serves primarily to provide a visual reference when driving them into the cement. Its dimensions prevent premature blockage at the edges of the neck cut.

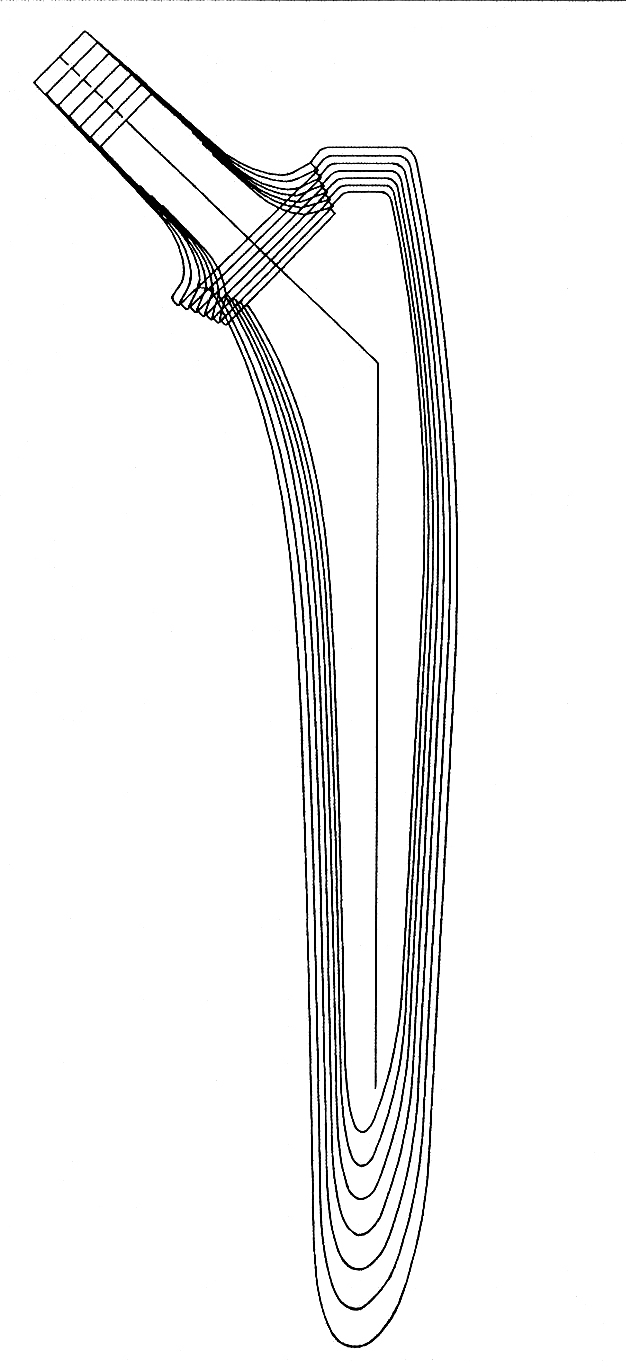

These stems are easy to insert into the cement thanks to the wide, progressive curvature of the trochanteric area, which respects the greater trochanter. The "distal ski" shape of the tip allows for excellent, intuitive centering in the cement and tends to keep the stem tip away from the lateral cortex.

The regular progression of the cross-section allows compression of the cement against the bone wall without producing a distal piston effect which pushes the cement distally as is the case with cylindrical stems with a hemispherical tip.

5.2.2.3. The first prosthesis created by stereolithography (3D printing)

These cemented Dustmann stems, created in 1991, were the first stems to be prepared using the stereolithography process, which has now become commonplace. The process for producing these stems required neither manual nor computer-aided design. Undimensioned drawings were subsequently produced only for administrative purposes. Today, the method is called 3D printing.

The files describing a stem, at the time on floppy disks, containing the coordinates of all the points and the contours defined to the nearest micron, were transmitted to a Company which transformed these files, using the I-deas software (later Unigraphics), into files directly usable by stereolithography equipment.

This device creates a life-size model of the prosthesis in a liquid resin, polymerized and hardened point by point and layer by layer, by a focused laser beam, successively traveling in X, Y, Z all the points of the entire volume of the stem.

5.2.2.4. The fastest production cycle

To prevent deformation of the resin prototypes, I had planned, when creating the stereolithography files, a cylindrical hole along the entire length to insert and seal a 6 mm stainless steel cylinder with epoxy resin.

To be able to perform anatomical tests directly with these consolidated prototypes, steel rasps were made from the shape of the resin prototypes.

As my design method and previous experience suggested, it was not necessary to change the shape of the stems, nor to make further prototypes. These stems are, to my knowledge, satisfactory and unchanged for 34 years.

After minimal manual finishing and polishing, I sent these resin prototypes to a major French precision forging company. Forging molds, obtained by copying the resin prototypes (with a few intermediate steps), enabled the mass production of the forged stainless steel blanks.

The forged blanks were then polished to a mirror finish and micro-blasted to obtain a satin finish and a surface hardening treatment. The necks, connecting cones, and extraction threads were then machined.

I provided all the control measurements and their positions, programmed and calculated simultaneously by my computer system. I defined the laser markings in detail, and especially their safe placement on the rods.

The entire process took only six months, instead of the usual two years.

The dimensional accuracy in both width and thickness was less than 100 microns at the end of the process, which is remarkable for forged parts that had not undergone any digital machining.

This precision, excellent for a cemented stem, would have been a little insufficient for a stem without cement.

----

Next implant: