2.8. The Principle of Extractibility

2.8.1. Summary

The Principle of Extractibility deals with the elements intended to make the extraction of a prosthesis geometrically possible.

An implant created according to the principles of Geometric Anchoring has the property of Extractibility. Care must be taken to ensure that no surface element, which could prevent the extraction of the implant, persists. Thanks to the Conical Junction between the implant and the bone bed, from the start of the extraction, the two components separate simultaneously at all their points of contact.

From the design of a prosthesis, its instrument and extraction method must exist as well as the technology for fixing the instrument to the implant. It is desirable that the instrument and its attachment be as simple and standardized as possible and, one day, normed.

Prostheses that are already osseointegrated benefit little from this property.

2.8.2. Extractibility

Reoperation of an orthopedic implant is not uncommon. It is always a very difficult intervention for the operator despite the very softened expression of “recovery”.

The designer of prostheses obviously cannot solve everything in advance but he must do his best to reduce, as much as his means allow, the difficulty linked to extraction, to minimize possible bone damage and to reserve the best " second line of defense ". For this, the geometric shape and the method of fixation of the implant in the bone must take into account the Principle of Extractibility. An extraction operating technique, instrumentation if necessary specific but as simple as possible, and the provision on the implant of the device for fixing the extraction instrument, are to be expected.

On the occasion of assisting with prosthetic revisions, I have noticed the difficulties of a geometric nature which complicated the work and the stress of any reoperation.

A large part of these difficulties can be eliminated when designing new implants by applying a few rigorous geometric rules.

2.8.3. It is necessary to avoid Hyperextractibility

The ability of the prosthesis to be extracted must not be pushed to the absurd by renouncing optimal fixation and to the point of creating hyperextractibility. There are prostheses on the market whose quality of fixation has been deliberately altered for the purpose of possible reoperation, which risks preventing secondary or even primary stability from being obtained.

With prostheses designed with excess extractability, all patients are penalized and present an increased risk of loosening, whereas we are only aiming to eliminate a hypothetical extraction difficulty which will only concern a small number. of them.

This is what we observe for example with uncemented stems whose distal region is polished. Stems with a bulky proximal part and a polished cylindrical distal part are a typical example of excess extractability.

Extractability considerations lose their validity for long-standing osseointegrated cementless stems.

2.8.4. Extractibility applied to stem SL Plus

If we have succeeded in initiating the extraction of the implant in the axial direction, all the surfaces which were in contact with the bone bed move away from it simultaneously thanks to the conical junction in the bone, which is at the base of its immobilization. No geometric element should oppose extraction without bone damage.

The first generation Zweymüller stems did not have the property of Extractability because:

1. on the one hand the 4 longitudinal grooves presented surface elements opposing extraction, even after very partial osseointegration. After fracture in my presence of 2 extraction hooks and a drill, it happened that the operator gave up extracting a stem of this type, even though it was infected.

2. on the other hand these rods had a proximal antero-posterior thickness less than the distal thickness.

The 1979 ZM stem did absolutely not satisfy the Law of Positive Derivatives, because it has thinner zones proximally than distally. The Hochgezogen ZM stem is more satisfactory, but has a lot of surface parallel to the axis, where the derivative in Z is zero and not positive. On the other hand, the AlloClassic and SL Plus stems perfectly satisfy the Law of Positive Derivatives (3.3.2.)

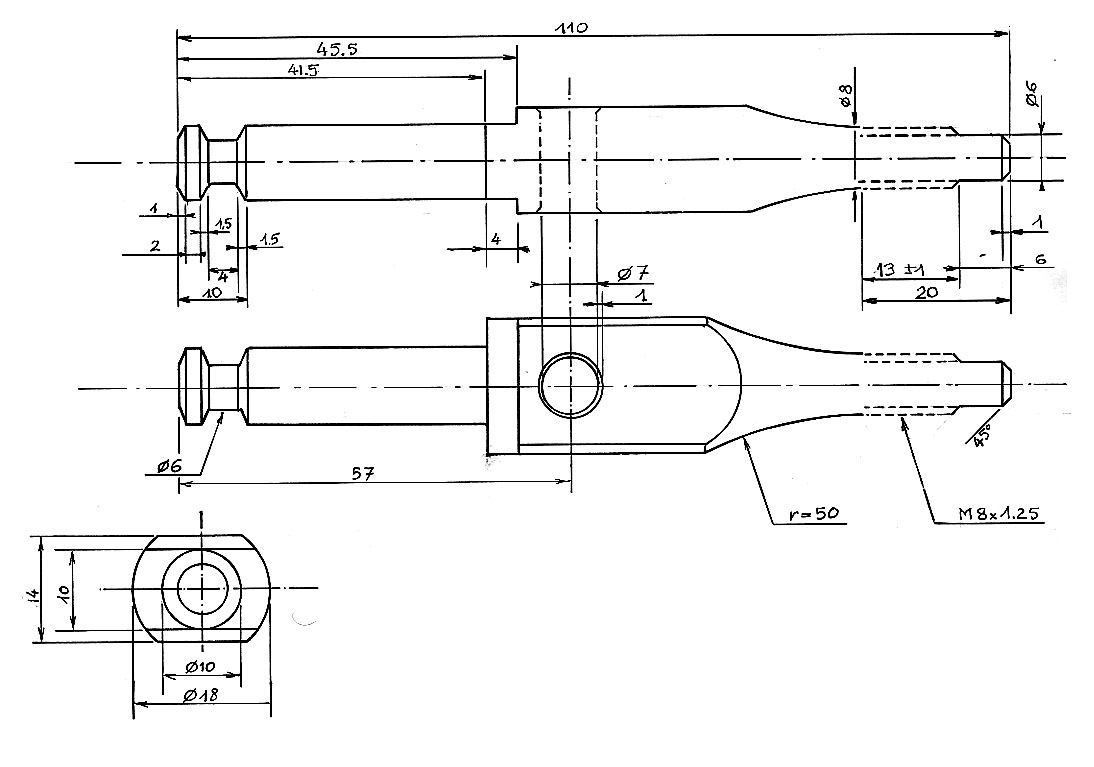

2.8.5. The instrumentation of extraction must be conceived as of the design of the implant

As on the majority of the prostheses of the market, the stems of M.E. Müller for example did not comprise any instrumental extraction device.

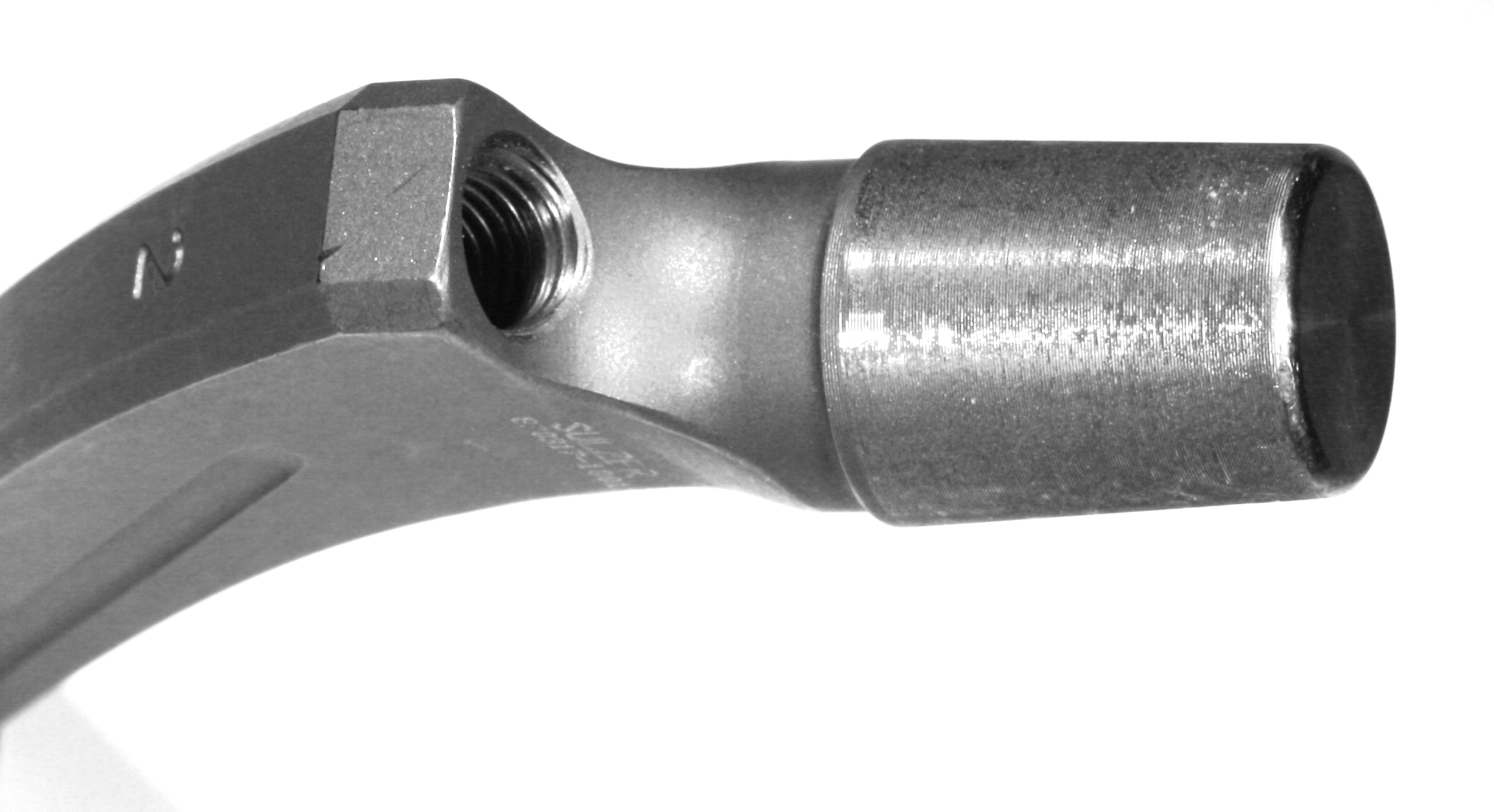

The hemispherical hole under the head was intended to place a pin remover. Striking with a hammer of the pin remover involved shocks in the direction of the trochanter, often causing cracks. One was to grasp the stem by the neck with any available grip, to strike with the hammer in any direction, to damage the grip, until the mobilization of the stem. The traces of the grip are visible on the photograph.

On the cemented prostheses of B.G. Weber existed proximal an extraction hole intended to receive an extraction hook of 6mm. For these cemented stems, this hook was undoubtedly sufficient. The form of the anchoring zone of the B.G. Weber stems satisfied practically the Principle of Extractibility.

On the stems of Zweymüller first generation, the hole of extraction and the hook of the stems of Weber were taken again.

2.8.6. The hook of extraction often insufficient

On the Zweymüller-AlloClassic stems, the extraction hole was positioned in the neck plane. The extraction hook mounted on the coaxial hammer remained unchanged. If this extraction hook was not sufficiently inserted into the extraction hole, it would twist at the first shock and came unhooked.

On several occasions, in my presence, to extract 1st generation stems, the extraction hook broke. Subsequently, for reoperations, I systematically brought 2 new extraction hooks for greater safety. Several times, the 2 hooks having broken, it was necessary to abandon the extraction.

Following these observations, I adopted, for the prostheses that I created from 1984 onwards, a much more powerful, reliable and very simple extraction device, the M8 thread.

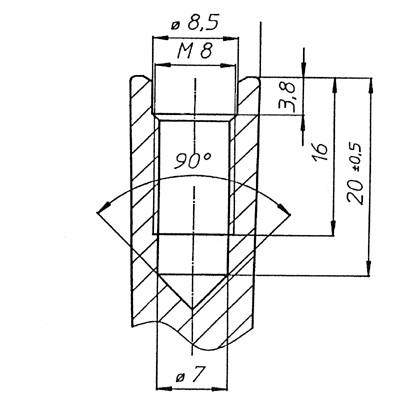

2.8.7. The extraction by the screw and its M8 threading

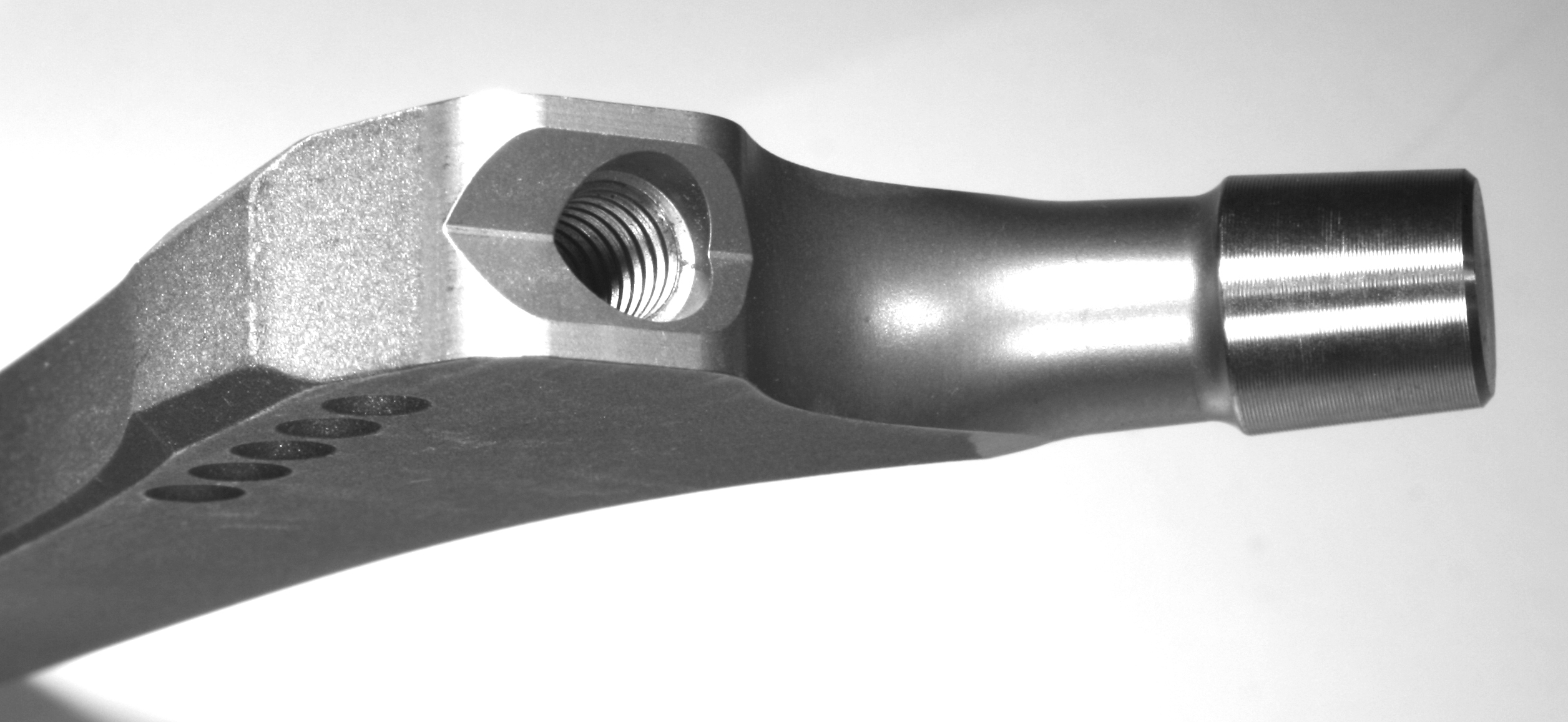

It is a threaded hole at the proximal end of the stem, accessible by a screw, after cleaning a minimum of conjunctive tissue.

A comparison in Test laboratory between a hook of extraction and a screw of M8 extraction screwed home would highlight a difference in tensile strength from 10 to 20 times higher in favor of the screw of extraction.

This metric thread M8 of standard step of 1,25mm is current in mechanics and a screw or a threaded rod comprising this standard threading could be bought in the trade even 30 years after implanting, in the event of need, whereas the original instrument of the prosthesis manufacturer is for a long time untraceable.

As I planned it for all my implants, to avoid any vibration, the tip of the extraction screw must be in truncated cone to 90° and the bottom of the threaded hole must also be 90° conical. During thoroughly screwing, about 10 turns of threading ensure a large surface of contact, the tapered tip is strongly centered, and it is the absence of movements and vibrations during the shocks, brought by this device and the simultaneous support on all the 10 turns which avoids damaging the 2 threadings.

Some mentioned the hypothetical risk to see bone to fill it this hole of extraction, risks never concretized, of ossified material being never established in a nonvascularized closed cavity and not undergoing any constraint. Only conjunctive material can be there.

Extraction and simple manipulation should not be confused.

The extraction screw used for the reoperations exploits all its power. On the other hand, a screw used only for handling does not require any power. A screw only intended for the handling of the prostheses of test could thus comprise only 5 whorls.

To date, I support always that this system of extraction threaded M8 should be applied to the majority of the prostheses of the market.

For other implants, a specific system of extraction with indication of the instruments and information on the details of procedure should always be available. As Member of the Commissions of Standardization, I had even wished to write a project of European Standard on the extractibility of the prostheses.

For a stem whose fixing is recent, the reoperation thanks to the screw of M8 extraction is easy, whereas other means of fixing as a transverse hook in a hole do not have already any more the sufficient power.

The screw of extraction assembled on a coaxial hammer has a remarkable effectiveness. It makes it possible to apply dry and powerful extraction shocks, without the threading of the stem or extraction screw not being damaged.

2.8.8. Examples of application

All projects of femoral stems, with or without cement, which I designed since 1986 envisage this threading of M8 extraction. Only some extra small sizes comprise a M6 threading.

ajouter photo Cs-plus Dustmann with tilted threading

No shock exerted during the extraction is directed towards the great trochanter. This way, the conflict between the great trochanter and the curved area of the cemented stem in the great trochanter is solved by a small elastic strain on the trochanter during the extraction without this deformation risking causing a crack.

2.8.9. The grooves of cementing respect Extractibility

The longitudinal grooves of the Holz-Zacher stem intended for its stabilization in the cement bed are also tilted in varus compared to the calculation axis of the stem, therefore compared to the axis of the diaphyse. The axis of these grooves is calculated parallel with contour médial zone of anchoring. Moreover, the grooves widen linearly according to their depth in direction of the point. The respect of the conditions of Extractibility ensures the simultaneous separation of the implant of its cement sleeve in all the points in the event of extraction. This geometry has the same behavior as a conical junction in the course of separation. The Law of the Positive Derivative is respected.

These grooves guide the first centimeters of the extraction of the stem and move away it, at the beginning of the way, the great trochanter with an aim of decreasing the risk of cracks.

Each of the three facets of the two cementing grooves, mathematically satisfied the extractibility conditions, and each one deviates in all the points of the contact with cement at the beginning of the extraction way, as it would be the case for a conical junction.

I remind that still flexible cement during the depression makes it possible the stem to follow a curved trajectory sparing the great trochanter, whereas during the extraction, when cement is hard, if the grooves were parallel to the stem axis, the stem would tend to enter in conflict with the great trochanter, whose elasticity is insufficient to resolve this conflict carefully.

The properties of extractibility which I applied to this cemented stem come from my experiment of reoperations of M.E.Müller self blocking stems whose trochanteric area presents an abrupt angle and cementing grooves parallel with the axis of the stem.

During the extraction, these grooves, which did not widen, inevitably guided the stem in the direction of the great trochanter, without allowing to deviate from it. If a delicate work of cement extraction, in the trochanteric area, was not carried out as a preliminary, the great trochanter was fissured.

Unfortunately, many stems of the market servilely took again this esthetics with oblique section of trochanteric area which increases the risks of cracks in the event of reoperation.

To solve this problem on the cemented right stem Holz-Zacher I adopted a continuous curve in the trochanteric area.

----

Next: The principle of Separation of the Roles of the Components