2.9. The Principle of Separation of the Roles of the Components

2.9.1. Summary

This is a general principle that should be applied as much as possible, both when designing an implant system and during the implantation procedure.

In a modular prosthetic system, regardless of the level of modularity, each component must be optimally exploited for its own function.

If a specific component is available to fulfill a second role, every effort should be made not to make a component that has been provided for an already defined role fulfill this second role.

This principle applies to the choices, orientations and settings of the components. Some examples are cited in the development of this Principle.

2.9.2. Principle of Separation of the Roles of the Modules of an Implant

This principle must be kept in mind when deciding to create independent modules that make up an implant. This principle must also be followed during implantation to prevent a component from playing a role that is not intended for it. If several components or adjustment possibilities are available, successive efforts must be made to exploit the main property of each component to the maximum by following a tree structure logic.

2.9.3. Example of Constant Necks and Heads

Metal neck length remained constant for all stem sizes of almost all prostheses, long after modular prosthetic heads allowing multiple neck lengths appeared on the market. The Operators were statistically led to implant a short-necked head for small patients to shorten the fixed neck, and a long-necked head to lengthen it for tall patients.

Used in this way, the variable length provided by the three heads was no longer set aside to compensate, at the end of implantation, for the residual differences in joint tension between the trial prostheses and the implanted stem. This role of compensation was wasted too early, to vary the collars of constant length.

Since I introduced the variation of the neck lengths by Growth Factors according to the sizes of stems, the lengths of collars are statistically adapted to the height of the patients. It is no longer necessary to use the different heads prematurely to compensate for constant cols. The role of reconstruction of the neck length must be provided by the stems.

To fulfill their real role, the neck lengths available in the heads must be reserved to compensate for residual positioning differences.

In this example, the necks of the stems and the necks of the heads each have their role.

2.9.4. Example of cup orientation

The typical example of this situation occurs when comparing a cemented one-piece polyethylene cup and a cup with a metal shell and polyethylene insert.

To prevent dislocation and ensure head coverage, cemented cups are frequently implanted in principle in a different direction from the orientation of the natural acetabulum and different from the orientation which would have ensured the largest fixation surface of the cup. . We can understand this attitude because there are few cemented cups whose entry is inclined or asymmetrical.

In the case of implantation of cups with a metal shell and separate insert, the preventive inclination of the shell is regrettable because the surface and the quality of fixation of the shell in the acetabulum is reduced. A part of the metal shell can sometimes protrude and come into conflict with the soft parts.

The ideal is to use an angled insert specially designed to provide stability to the head in a direction different from that of the shell. When an antiluxation insert is available, it is best to first orient the shell so that it is in broad contact with the bone, and only then concern itself with stability and coverage of the head by orienting correctly the insert.

In this example, to properly separate the functions of the components, the shell must be oriented to fully play its role of fixing the implant while the inclined insert plays the role of stabilizing the head.

2.9.5. Example of the role of the Ascending Interlocking in the reconstruction of Total Bone Length

This paragraph concerns one-piece stems but also the distal stems of modular prostheses, before the choice of the proximal piece.

The property of Ascending Interlocking makes it possible to know in advance the differences in height between two sizes of consecutive rods in the same prepared bone bed.

To obtain satisfactory stability, it often happens that an extra long and even extra extra long neck head is used when it would have sufficed, in the same situation, to implant a larger stem with a short or medium neck. To achieve an intermediate height, an additional grating cycle may be useful.

The result obtained by implanting the stem of the larger size offers a much better overall reliability of the prosthesis than the use of extra long necks.

The slightly longer metal neck in the next size provides a little extra advantage. The stem metal neck and conical junction are less stressed than with an extra long neck head.

Extra long neck ceramic heads exist but require an additional metal sleeve increasing the risks.

Extra long neck heads require a "skirt" which significantly increases the diameter of the neck under the head, losing 8 to 12° of total travel compared to S, M and L heads. The risk of dislocation is unnecessarily increased. XL and XXL necked heads should be reserved for exceptional uses ( 6.2.2. my Draft European Standard, page 19, § 3.2.2. ). If there is a need to lateralize the femur, lateralized neck stems, if available, should be implanted.

In this example, the role of the Ascending Interlocking is to provide most of the Total Bone Length, the role of the standard heads is to compensate for small deviations and the XL and XXL necks are to be reserved for otherwise unsolvable cases, such as reoperation with stem in place.

2.9.6. Example of extra long necks and proximal pieces

This paragraph concerns modular prostheses and in particular the Modular Plus stems. In the rod systems that I have designed and which include the property of Ascending Interlocking, it is absolutely necessary to choose the size of the distal stem allowing to obtain the best possible fixation allowed by the shape of the femur, by the thicknesses of diaphyseal cortical still present and for better preservation of the bone capital.

Knowing that the height of the junction on the modular rod can be obtained by steps whose distance is foreseeable by the Ascending Interlocking ( 4.7.2.5. ), it is practically not necessary to Consider final height when choosing distal stem size.

During the preparation, it is only necessary to concentrate on the sufficient length of the medullary canal rectified by the Spiral Reamer, especially taking into account the thickness of the supporting cortical bone at the end of the reaming. It is for the separation of roles philosophy that reaming should be done for ideal bone preparation and not to fit a rod size.

For the choice of the trial rod that will be tested first, it is sufficient to orientate oneself towards the size defined during the planning.

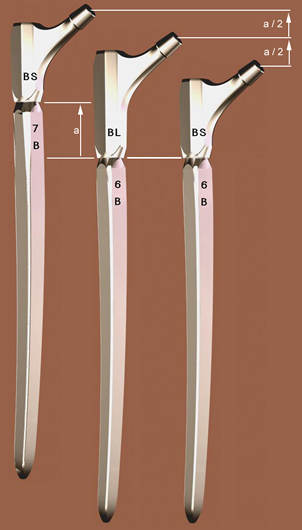

Two heights of proximal pieces are provided in the Modular Plus system and the long proximal piece brings head level to half the range achieved by standard proximal pieces mounted on two consecutively sized stems.

A few additional turns of reaming will allow the distal stem to be pushed in a little and achieve any intermediate height. Under no circumstances should XL or XXL neck heads replace these possibilities because with XL and XXL necks, the junction of the proximal part to the distal part risks being overstressed.

Dans ce système, je n'ai pas prévu une troisième pièce proximale encore plus haute car cela n'aurait aucun sens.

2.9.7. Example of Antetorsion and modular proximal parts

The curved stems of the Modular system must be implanted with the orientation allowing ideally following the anterior curvature of the femur without wanting to influence, at this stage, the Antetorsion orientation that the stem will naturally adopt. The antetorsional orientation of the assembled prosthesis is subsequently obtained with the proximal part adjustable through 360°. The Principle of Separation of Roles is respected, the stem satisfies the anterior curvature of the femur then the proximal part satisfies the antetorsion.

2.9.8. This principle cannot be satisfied with one-piece femoral stems, for antetorsion

This Principle cannot be satisfied with AlloClassic, SL Plus and cemented stems because correct cervical antetorsion can only be achieved by orienting the entire stem in the direction evaluated. The anchoring zone of the stems is therefore not in the ideal direction for the best filling of the medullary canal.

It was already known with the first generation Zweymüller stems with a flattened rectangular section that it was an antetorsion close to zero that made it possible to implant the largest possible rod. Rotating the neck by 20 to 25° in antetorsion statistically caused a loss of one stem size.

It is as a result of this reflection that I subsequently (Ana Nova project), created curved modular stems satisfying to the highest degree the Principle of Separation of Roles of the components of an implant.

----